Saujanya

Dye Stuffs M Brand Dyes (Dichlorotriazine)

Saujanya

Dye Stuffs M BRAND DYES are highly reactive requiring

comparatively milder conditions in dye fixation. They

are primarily of interest in dyeing at normal room

temperature (about 25º - 30º Deg. C) using Soda Ash

or Sodium Bicarbonate. Saujanya Dye Stuffs M BRAND

dyes are applicable to cellulosic textiles by Batch-wise,

Semi-continuous and Continuous methods in conventional

textile machinery like open-vat, Package, Jet, Jig,

Winch and padding mangle. The versatility in various

application procedures and the availability of wide

range of bright and fast shades are the outstanding

features of this class of dyestuffs.

General

Characteristics Of 'M' Brand Dyes

Stability

The

dyestuff should be stored in cool and dry conditions.

The containers should be tightly closed when not in

use. High temperature, Humidity and alkaline pH conditions

reduce the stability of the dyes in solution.

Water

supply

Soft

of the softened water should be employed, avoiding

alkalinity especially while dissolving the dyes, when

hard along is available, it should be softened with

sequestering agents. In dyeing, the pH of the water

supply should be within the limits pH -7-8.

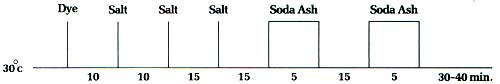

Method

Dyeing

Receive

cold water in the dye bath (Recommended m/l ratio

1 to 15), add required quantity of common salt or

gluber salt. Paste required dyes with the water and

dissolve by adding water 30º C to same. Add dissolved

dye to the dye bath. Enter material, run 15 to 20

minutes. Add required amount of soda ash (as solution),

run material for 45 to 60 minutes, squeeze, wash with

water and soap at boil with 2g/L soap, wash with water

and dry. Soaping treatment is highly essential to

remove unfixed dye to produce dyeings of high washing

fastness.

Standard Exhaust Methods

for Cold Brand Reactive Dyes

Salt & Alkali Requirement

for Cold Brand Reactive Dyes

Depth

of Shade % |

Salt

g/l (Dye Liquor) |

Soda

Ash g/l (Dye Liquor) |

Up

to 0.5 |

30 |

3 |

0.5

to 2.0 |

40 |

4 |

2.0

to 4.0 |

50 |

7 |

Above

4.0 |

60 |

10 |

Reactive

Cold Brand Dyes |

FASTNESS

PROPERTIES |

| |

Light |

Washing |

Perspiration |

Hypochlorite |

Dischargeability |

Red

M5B

Red - 2 |

|

4-5 |

4-5 |

3-4 |

1 |

P |

Red

M8B

Red - 11 |

|

4-5 |

4-5 |

2 |

4 |

P |

Magenta

MB

Voilet - 13 |

|

4-5 |

5 |

4-5 |

1 |

F |

Orange

M2R

Orange - 4 |

|

5 |

5 |

4 |

4 |

P |

Orange

M2RJ

|

|

3-4 |

4 |

4 |

4-5 |

P |

Gol.

Yellow MR

Yellow - 44 |

|

5 |

4-5 |

4 |

1 |

P |

Yellow

MR EX H/C Yellow - 44 |

|

5 |

4-5 |

4 |

1 |

P |

Yellow

M3R

Yellow - 36 |

|

6 |

5 |

4 |

2 |

G |

Yellow

M4R

Orange - 14 |

|

5 |

4-5 |

4 |

1 |

P |

Yellow

M8G

Yellow - 86 |

|

6 |

4-5 |

4-5 |

1 |

G |

Yellow

M4G

Yellow - 22 |

|

6 |

4 |

5 |

1 |

G |

Yellow

MGR

Yellow - 7 |

|

6 |

5 |

4-5 |

4-5 |

P |

Violet

C4R

Violet - 12 |

|

4 |

3 |

4 |

1 |

P |

Violet

C2R

Violet - 14 |

|

3-4 |

3 |

4 |

1 |

P |

Blue

MR

Blue - 4 |

|

6 |

5 |

5 |

2 |

P |

|

Reactive

Cold Brand Dyes |

FASTNESS

PROPERTIES |

| |

|

Light |

Washing |

Perspiration |

Hypochlorite |

Dischargeability |

Blue

M2R

Blue - 81 |

|

6 |

5 |

4-5 |

1 |

P |

Blue

M2R H/C

Blue - 81 |

|

6 |

5 |

4-5 |

1 |

P |

Navy

Blue M3R

Blue - 9 |

|

5 |

4-5 |

3 |

3 |

P |

Blue

M4GD H/C

Blue - 168 |

|

6 |

5 |

3-4 |

2 |

P |

Tur.

Blue MGN

Blue - 140 |

|

6 |

4 |

4 |

2-3 |

P |

Tur.

Blue Ha5G

Blue - 71 |

|

6 |

3-4 |

4-5 |

3-4 |

P |

|

Reactive Cold Brand Dyes Manufacturer

& Exporter in Ahmedabad Gujarat India Asia |